People are shocked after discovering the surprising process behind how pre-packaged sandwiches are made and prepared for sale.

Many people love the convenience of pre-packed sandwiches. They are quick to grab for lunch or a snack.

However, recent revelations about how these sandwiches are made have left many feeling uneasy.

A YouTube video from the series How It’s Made has sparked a big conversation about the production process behind these popular meals.

The video shows a factory in America where pre-packaged sandwiches are made.

It starts by explaining that retailers tell the factory what ingredients to use.

Based on these orders, the factory organizes its assembly lines.

How are pre-packaged sandwiches really made?

There are two main methods for making pre-packaged sandwiches.

The first method combines manual labor with machines.

In this process, workers begin by placing fresh bread slices into a machine.

They check each slice for any defects, like holes or tears.

Once the bread is ready, the machine spreads melted butter on the slices.

Then, an automated system adds mayonnaise according to the customer’s specifications.

After this, workers manually add other ingredients, such as meats and cheeses.

This part of the process surprised many viewers because the workers were not wearing gloves while handling the food.

Next, the factory uses a slicer to cut ham into the desired size.

Again, this step is done without gloves, which raises concerns about food safety.

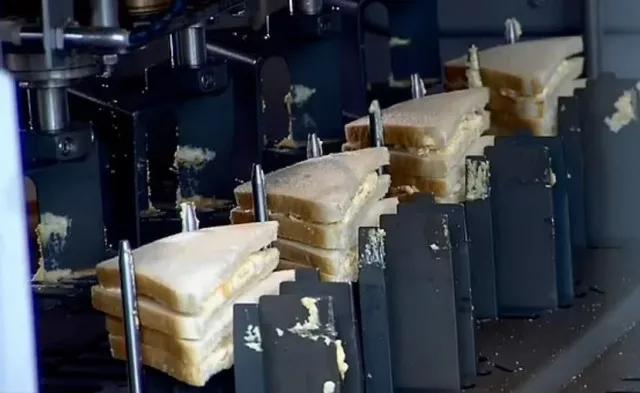

After the ingredients are added, the sandwiches are closed, stacked, and sent to a machine that cuts and packages them.

Fully automated process

The second method is fully automated and is used when large quantities of sandwiches are required.

In this case, robots handle most of the work. A robot picks up bread slices and places them on a conveyor belt.

The slices are adjusted to ensure they fit perfectly under machines that dispense fillings.

For example, when making egg salad sandwiches, a nozzle drops a specific amount of egg and mayonnaise onto every second slice of bread.

After that, robotic arms flip the slices over and an ultrasonic knife cuts the sandwiches in half.

Finally, the sandwiches are placed into plastic trays, sealed, and labeled.

This fully automated process is efficient and quick, allowing sandwiches to reach store shelves within just 12 hours of production.

People vow to never eat pre-packaged sandwiches again

After watching the video, many people expressed shock and concern.

Some viewers commented on the lack of gloves, saying it made them rethink their choices.

A viewer from a school kitchen was surprised to see food handled without gloves, especially for mass-consumed products.

Others shared their feelings of betrayal. They felt uneasy knowing that multiple workers touched the sandwiches before they were packaged.

Some even vowed to avoid pre-packaged sandwiches altogether after seeing the video.

It’s been years since I bought a pre-made sandwich, and after seeing this, I can say it will be even longer now, one user said.

Thank you for this video. No more eating packaged sandwiches! The second user wrote.

That’s why I cook my own Food!! The third user commented.

The same way all fast food is made, another user wrote.

I make my own. Bet they don’t wash their when going toilet or having a cigarette break. Never would I eat a pre-made one, someone said.