Train wheels are shaped like a truncated cone instead of a perfect circle to help trains stay balanced and run smoothly.

When we think about train wheels, we often picture them as simple circles.

However, if we take a closer look, we will see that train wheels are shaped more like a truncated cone than a perfect circle.

This unique design is not just for looks; it plays an important role in how trains operate on tracks.

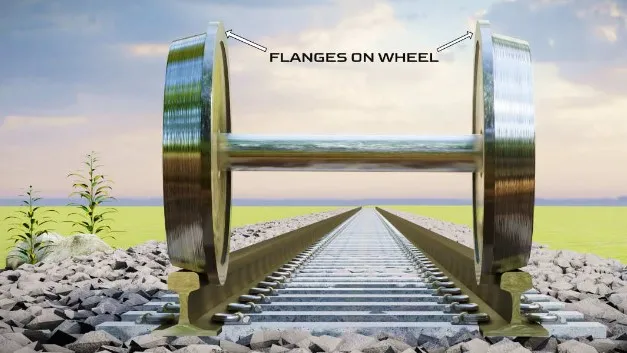

Understanding the shape of train wheels

Train wheels are not exactly cylindrical. They have a slight conical shape.

The wider part of the cone points towards the inside of the train, while the narrower part points outward.

This design is crucial for keeping the train on the tracks, especially when it moves around curves.

When a train moves straight, both wheels on an axle turn at the same speed.

This works well on straight tracks.

However, when the train approaches a curve, the situation changes.

Because of the curve’s shape, the outer wheel must travel a longer distance than the inner wheel.

If both wheels were perfect circles, the train could easily derail.

How does the conical shape help?

The conical shape helps solve the problem of curves.

When the train goes around a bend, the wheel on the outside of the curve rolls further than the wheel on the inside.

The taper of the conical wheel allows it to adjust to this difference in distance.

As the train navigates through the curve, the wheels help guide the train back towards the center of the track.

This self-centering effect keeps the train stable and reduces the risk of derailment.

The slightly sloped sides of the wheels help them stay aligned with the track, making for a smoother ride.

The physics behind train wheels

The design is based on basic physics principles.

When the train moves straight, the forces acting on the wheels are balanced.

The angle of the conical shape means that any sideways forces acting on the wheel are directed towards the center of the track.

This helps the train maintain its path without veering off.

Additionally, the conical shape creates a differential effect.

This means that the outer wheel can rotate slightly faster than the inner wheel without losing contact with the track.

This ability to adapt to different speeds is crucial when the train turns, allowing it to move efficiently and safely.

Benefits of the truncated cone design

One major benefit of the truncated cone shape is its ability to reduce wear and tear on the wheels and tracks.

When trains navigate curves, the design helps distribute the weight evenly.

This reduces the stress on the wheels and the tracks, leading to less damage over time.

Moreover, the conical shape helps with maintenance.

Wheels that are not perfectly circular can often self-adjust, which means they may not need to be replaced as frequently.

This can save time and money for train operators.