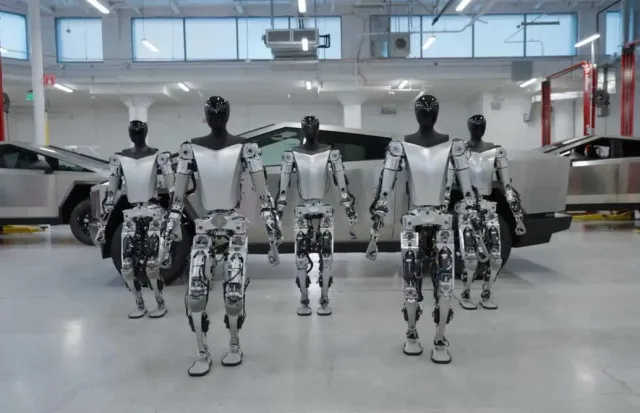

A Tesla robot attacked an engineer at a Texas factory, causing panic among workers and prompting an emergency shutdown.

Recently, a serious incident occurred at Tesla’s Giga Texas factory that left many people shocked.

A robot, which is designed to help in the manufacturing process, attacked an engineer.

This event raised alarms about safety at the factory and the use of robots in workplaces.

Tesla robot causes heated panic after attacking an engineer at a Texas factory

The worker involved was a software engineer who was programming robots designed to cut aluminum car parts.

While repairing two robots, workers mistakenly left a third robot on.

Witnesses reported that the robot suddenly pinned the engineer down and dug its metal claws into his back and arm.

This caused significant injuries and left blood on the factory floor.

Despite the severity of the attack, Tesla claimed that the engineer did not need to take time off work.

However, an injury report submitted to health authorities detailed that he suffered a “laceration, cut, or open wound” on his left hand.

This report has raised questions about how injuries are recorded at the factory.

Data from the U.S. Occupational Safety and Health Administration (OSHA) shows that nearly one in every 21 workers at the Giga Texas factory was injured last year.

This rate is much higher than the industry average, which stands at one in every 30 workers.

Current and former employees have expressed concerns that Tesla often cuts corners in construction and safety practices, putting workers at risk.

Hannah Alexander of the nonprofit Workers Defense Project said:

“My advice would be to read that report with a grain of salt. We’ve had multiple workers who were injured,”

“And one worker who died, whose ịnuries or death are not in these reports that Tesla is supposed to be accurately completing and submitting to the county to get tax incentives.”

The factory has been the site of other safety issues as well.

Employees have reported incidents where heavy machinery fell near them.

Additionally, some have suffered illnesses from exposure to harmful substances like ammonia.

Last summer, a moving cart caught a worker’s ankle, causing a significant work absence.

In another alarming incident, an explosion occurred in the casting area after water accidentally mixed with molten aluminum.

This explosion sent flames and smoke into the air, causing panic among workers.

Officials did not document the extent of injuries from this event in safety reports.

Tesla began construction on the Giga Texas factory in 2020, aiming to produce millions of cars annually.

Management continues to focus on fast production, raising ongoing concerns about worker safety as the facility develops.

As Tesla continues to expand, the company must prioritize the safety and well-being of its employees to prevent further incidents like this one